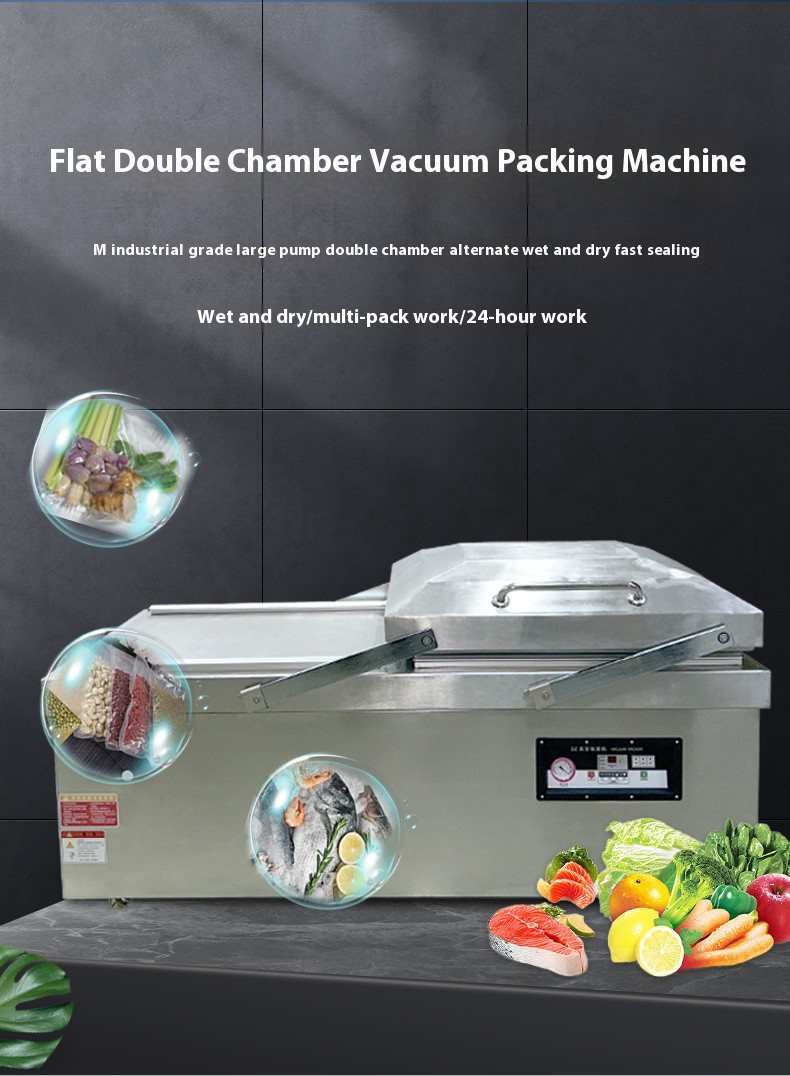

The alternating operation of the two vacuum chambers in the double-chamber vacuum packaging machine improves efficiency.

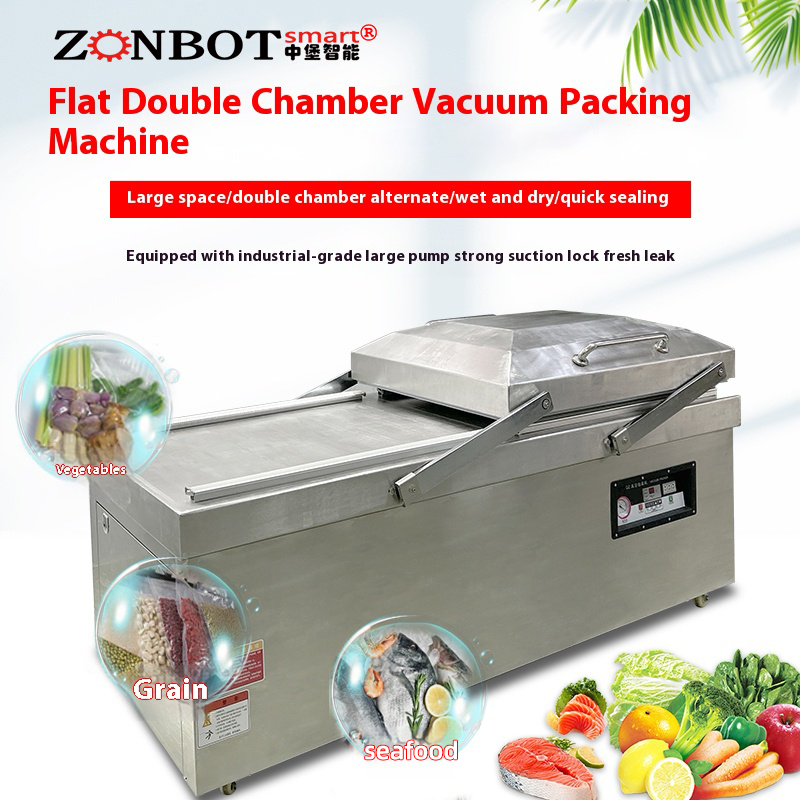

The double-chamber vacuum packaging machine is a type of packaging equipment commonly used in the food, pharmaceutical, electronics, and other industries. It packages products in a vacuum environment through operations such as vacuuming and sealing to extend the product's shelf life and improve preservation effectiveness. Below is a detailed introduction to it:

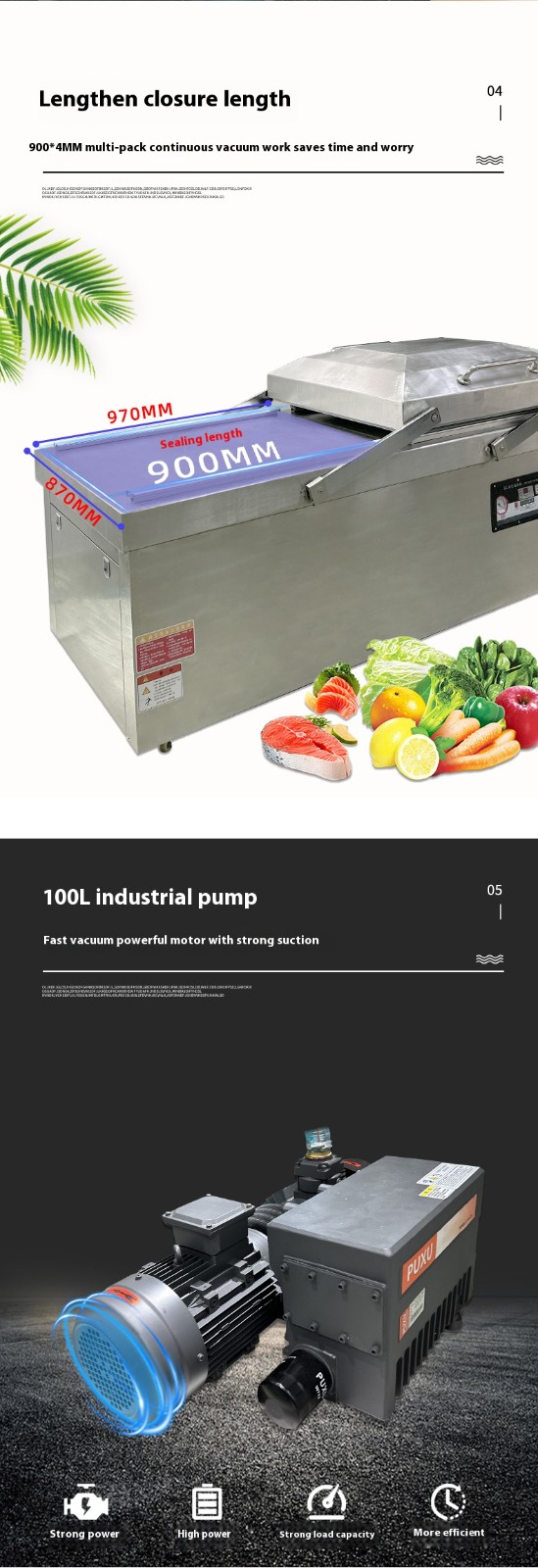

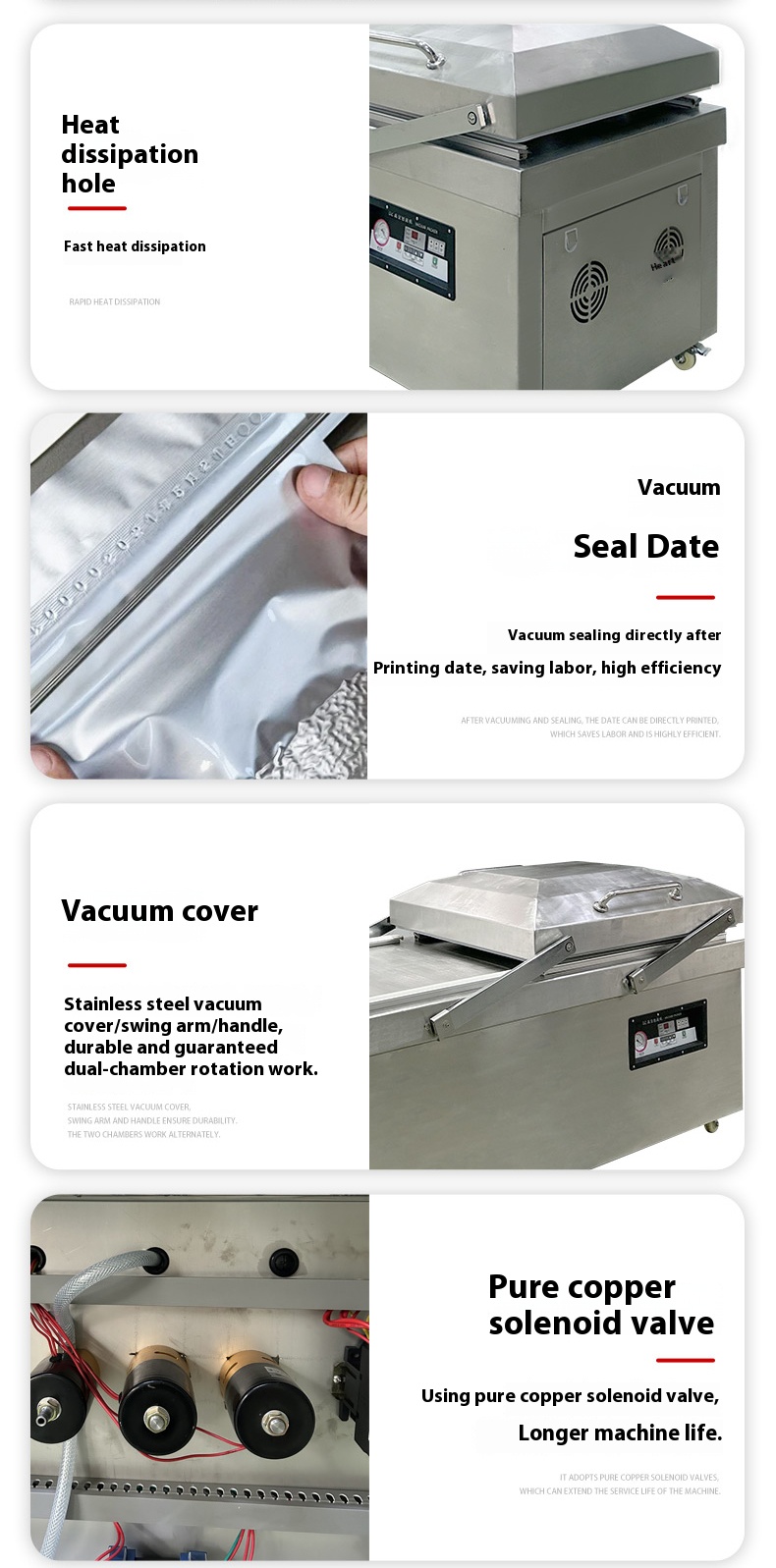

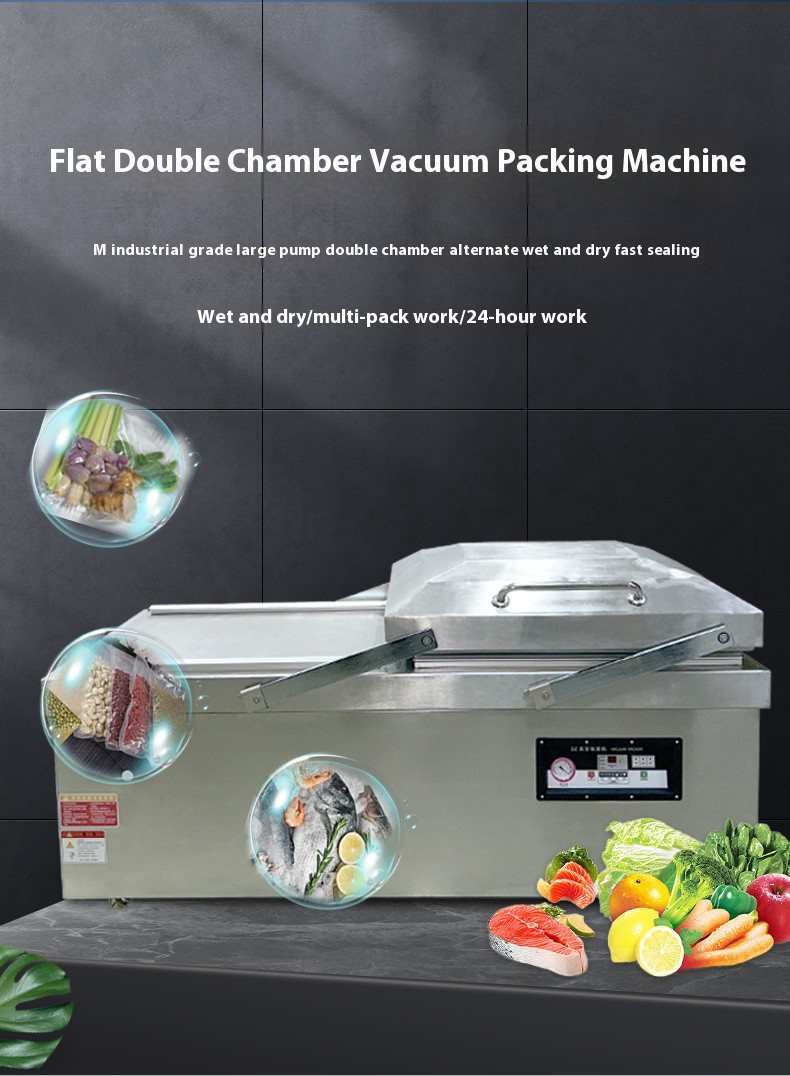

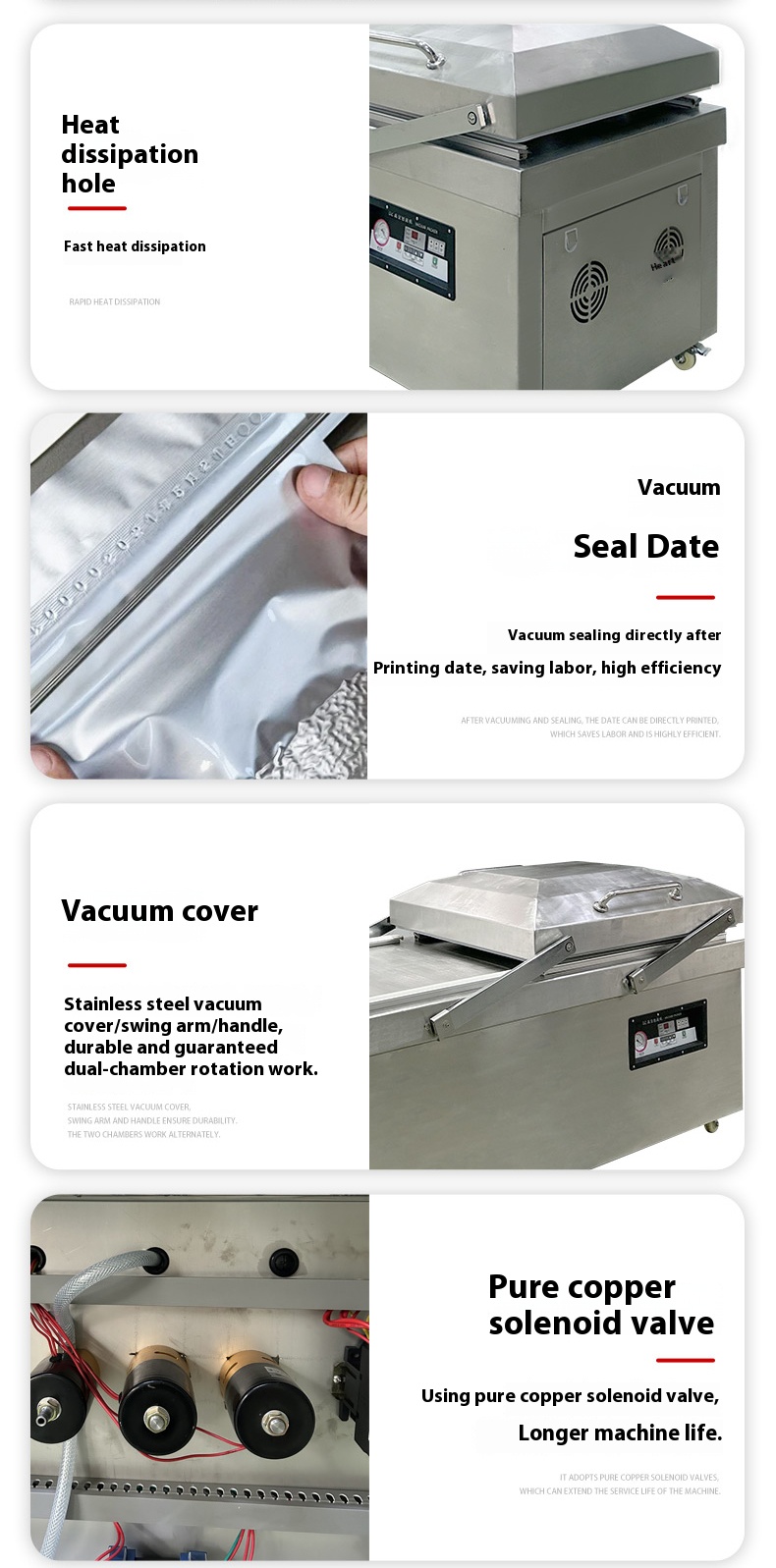

The two vacuum chambers of the double-chamber vacuum packaging machine work alternately. When one vacuum chamber is closed, the vacuum pump starts operating to vacuum the chamber and the packaging bag. Once the rated vacuum level is reached, the vacuum pump stops working. Next, the two-position three-way solenoid valve operates to create a vacuum in the heat-sealing air chamber. The heat-pressing frame moves down to press the bag mouth, and the heat-sealing transformer works to seal the bag. After sealing is completed, the two-position two-way solenoid valve opens, allowing atmospheric air to enter the vacuum chamber. The heat-pressing frame resets by means of a return spring, the vacuum chamber lid opens, and then the upper vacuum chamber moves to the other vacuum chamber to start the next working cycle.

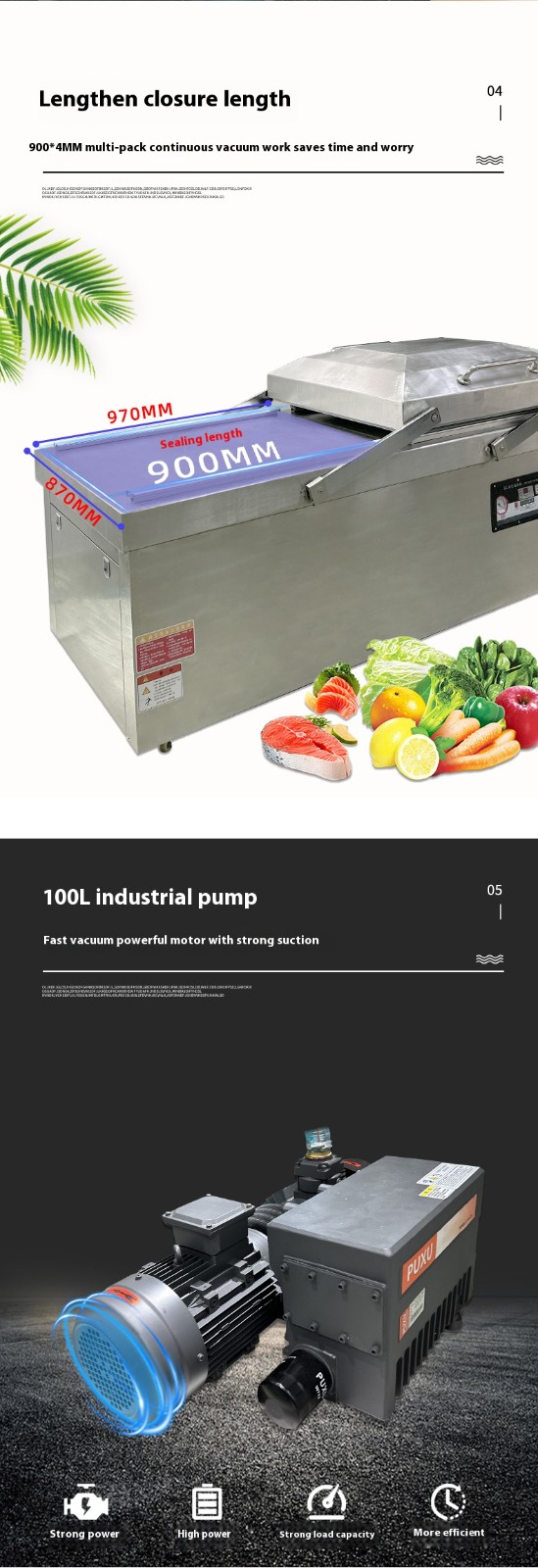

- High Efficiency: The two vacuum chambers work alternately, reducing downtime during the packaging process. This enables faster and more efficient packaging of large quantities of products, improving production efficiency.

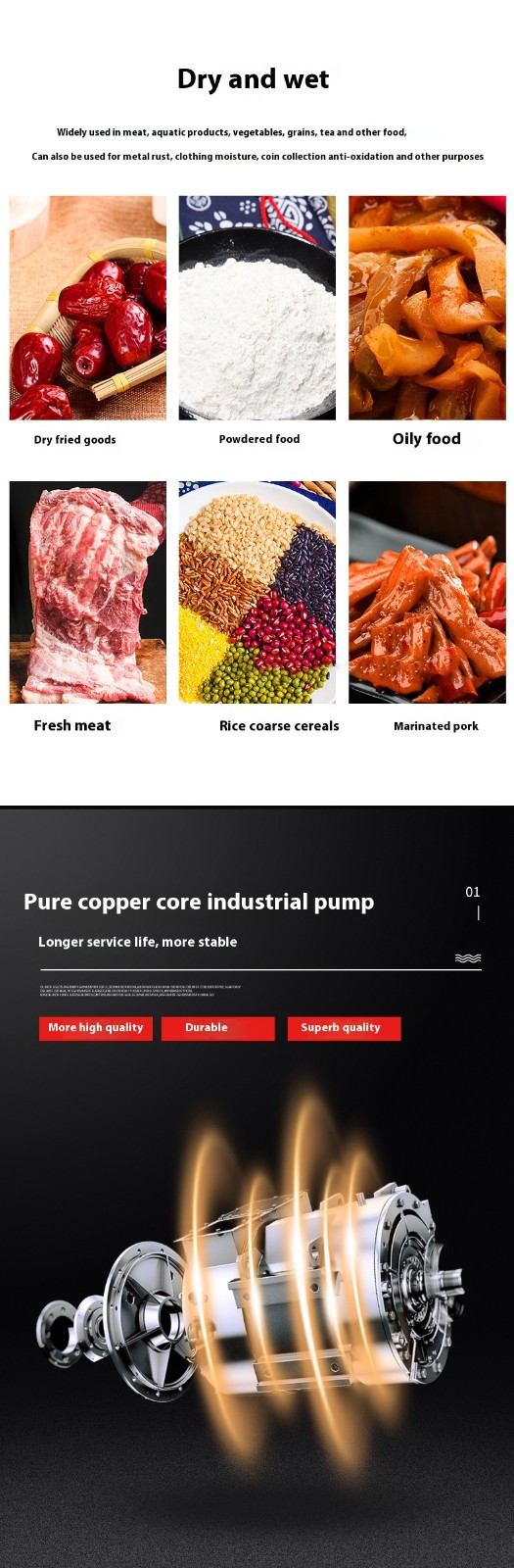

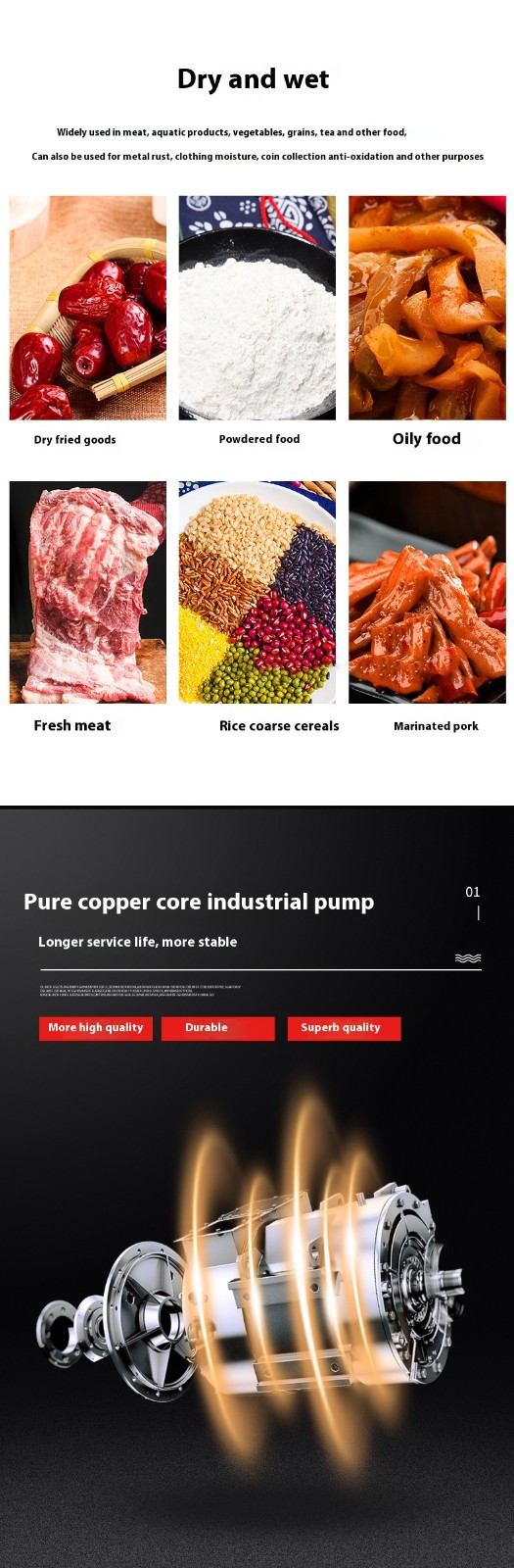

- Versatility: It can perform operations such as vacuuming, sealing, and gas filling. By filling inert gases like nitrogen, it achieves better preservation effects such as anti-corrosion, moisture-proofing, and anti-oxidation discoloration. It also allows setting different parameters (e.g., vacuum level, sealing time) according to the requirements of different products.

- Stability: The frame is made of stainless steel, which has high strength and is not easily damaged. Some models also have waterproof and moisture-proof functions. Its key components (e.g., vacuum system, heating system) have stable performance, ensuring reliable long-term operation of the equipment.

- Easy Operation: It usually adopts programmable logic controller (PLC) and color touchscreen operation. The interface is intuitive and user-friendly, allowing operators to easily set various parameters and programs.

It is widely used in the food, electronics, pharmaceutical, and other industries. In the food industry, it can be used to package various cooked products, pickled products, soy products, preserved fruits, etc. In the electronics industry, it can vacuum-package electronic products, circuit boards, electronic components, etc., to prevent oxidation and moisture damage. In the pharmaceutical industry, it can be used to package medicines, medical devices, etc., to ensure their quality and safety.